CY20K1700 collaborative palletizing workstation

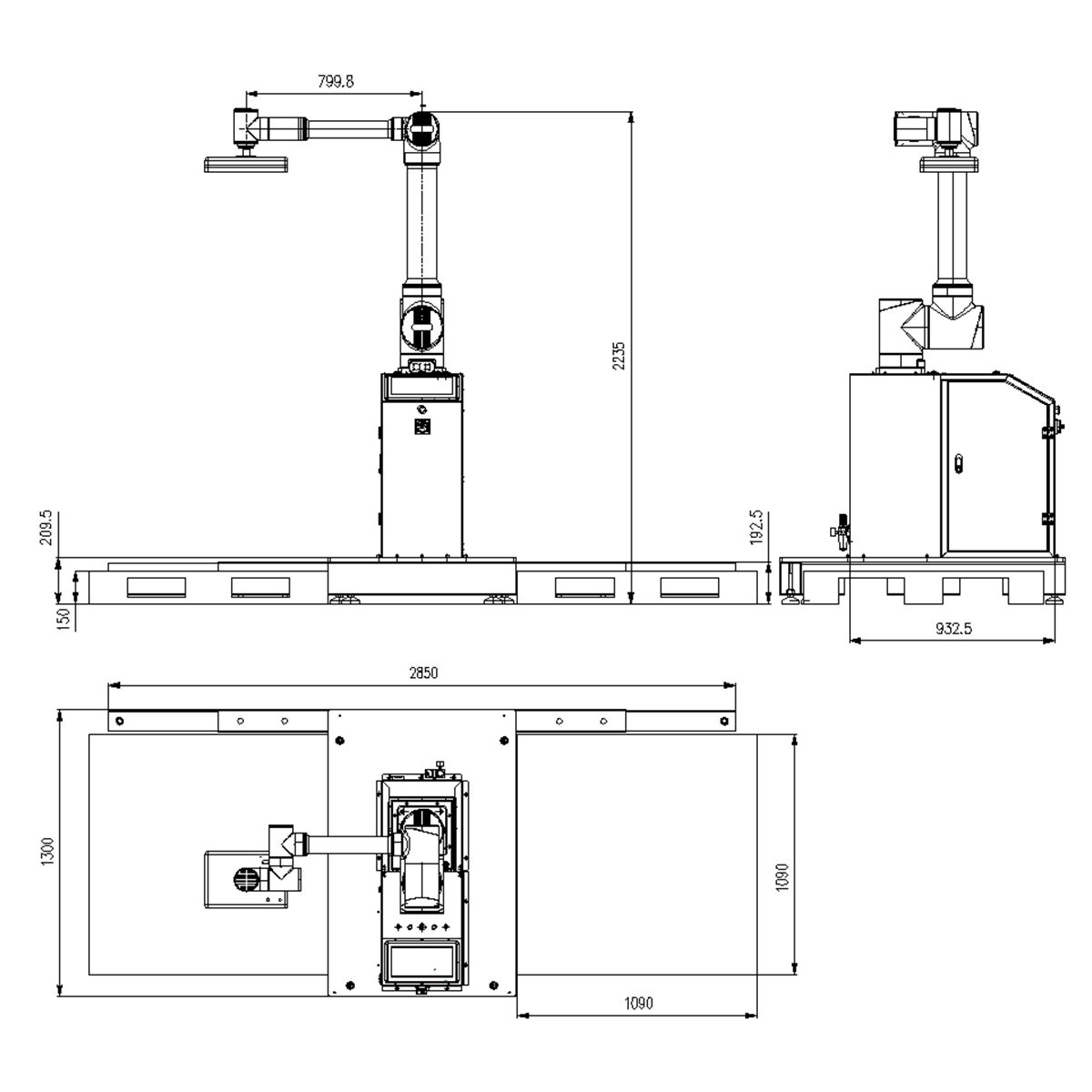

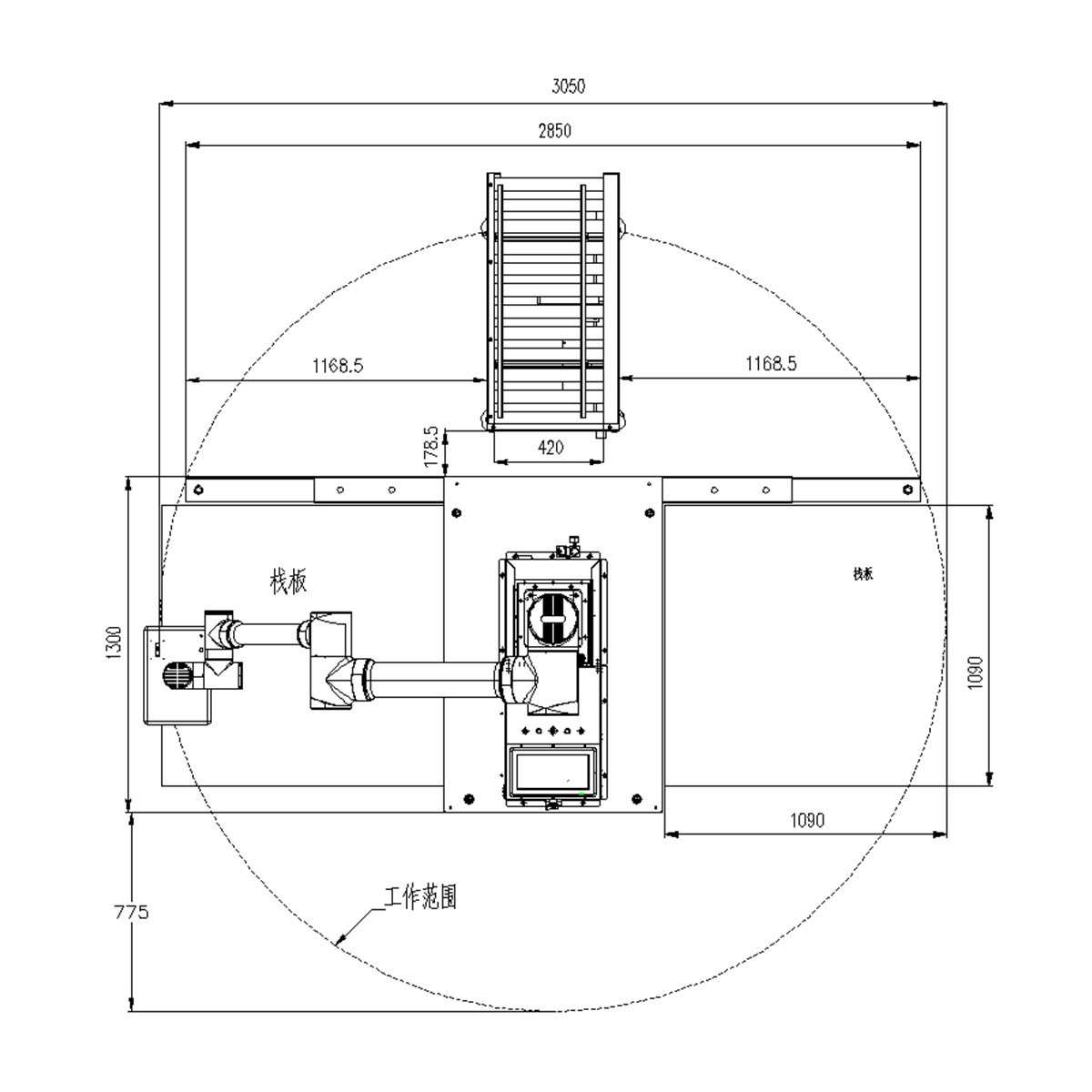

1.Three views of collaborative palletizing workstations:

2.Workstation:

1. Workstation composition

1.Collaborative Robot.

2 Electric Box Control Cabinet .

3.Column Lifting Axis.

4.Base&Card Board Positioning.

5.End Effector.

6.Operating System.

2, Workstation Workflow:

Preparation → Palletizing Mode Setting → Pallet a→ Pallet b→ Complete

3. Product advantages:

1. Safe and stable:

(1).Able to work directly side by side with humans without using safety fences for isolation, with high reliability and safety;

(2).Supports 10-level collision detection and sensor safety detection;

(3).Providing 16 safety I/O interfaces, the safety function will not be lost in the event of a single fault;

(4).The terminal will not fall when power is turned off, and the product is safe and stable;

2. Flexible deployment:

(1) Integrated design, light and flexible, small footprint;

(2) Workstation deployment of new tasks is simple, fast and efficient;

3. Simple programming:

(1) It takes half an hour to master the programming method, and one hour to complete simple programming;

(2) Visual programming is simple and efficient, and you can easily control the robot without being proficient in programming languages;

4. Flexible production:

Quickly switch between multiple functional scenarios, and can use human-machine collaboration, dual-machine collaboration, multi-machine collaboration, etc. to achieve flexible production;

5. Wide application:

Widely used in food, medicine, 3C, daily chemicals, e-commerce and other industries;

4. Specification:

Specification | ||||

Body weight | 82kg | |||

Payload | 20kg | |||

Working radius | 1525mm | |||

Reach range | 1730mm | |||

Rated voltage | 220v | |||

Typical speed | 1.0m/s | |||

Max motion range | J1 | ±170° | ||

J2 | ±170° | |||

J3 | ±170° | |||

J4 | ±170° | |||

J5 | ±170° | |||

Max speed | J1/J2 | 89 °/s | ||

J3 | 158 °/s | |||

J4/J5 | 178 °/s | |||

Control box | DI | 16 digital inputs | ||

DI/DO | 16 digital outputs | |||

Repetitive positioning accuracy | ±0.1mm | |||

Communication methods | EtherCAT | |||

IP level | IP54 | |||

Temperature Range | 0-50℃ | |||

Typical power consumption | 2000 W | |||

Mterial | Aluminum, steel, rubber, plastic | |||

Palletizing workstation | ||||

Maximum stack height* | The maximum stackable height for lifting and lowering is 1800 mm (excluding pallets); Generally up to 1650mm (excluding pallets) | |||

Maximum pallet size* | 1100mm×1100mm | |||

Stackable box size* | L(200-500)mm*W(150-450)mm*H(150-400)mm | |||

Maximum allowable load | 20kg | |||

Fastest stack speed | Stacking up to 8 boxes/min | |||

Working radius | 1525mm Maximum working radius 1525mm | |||

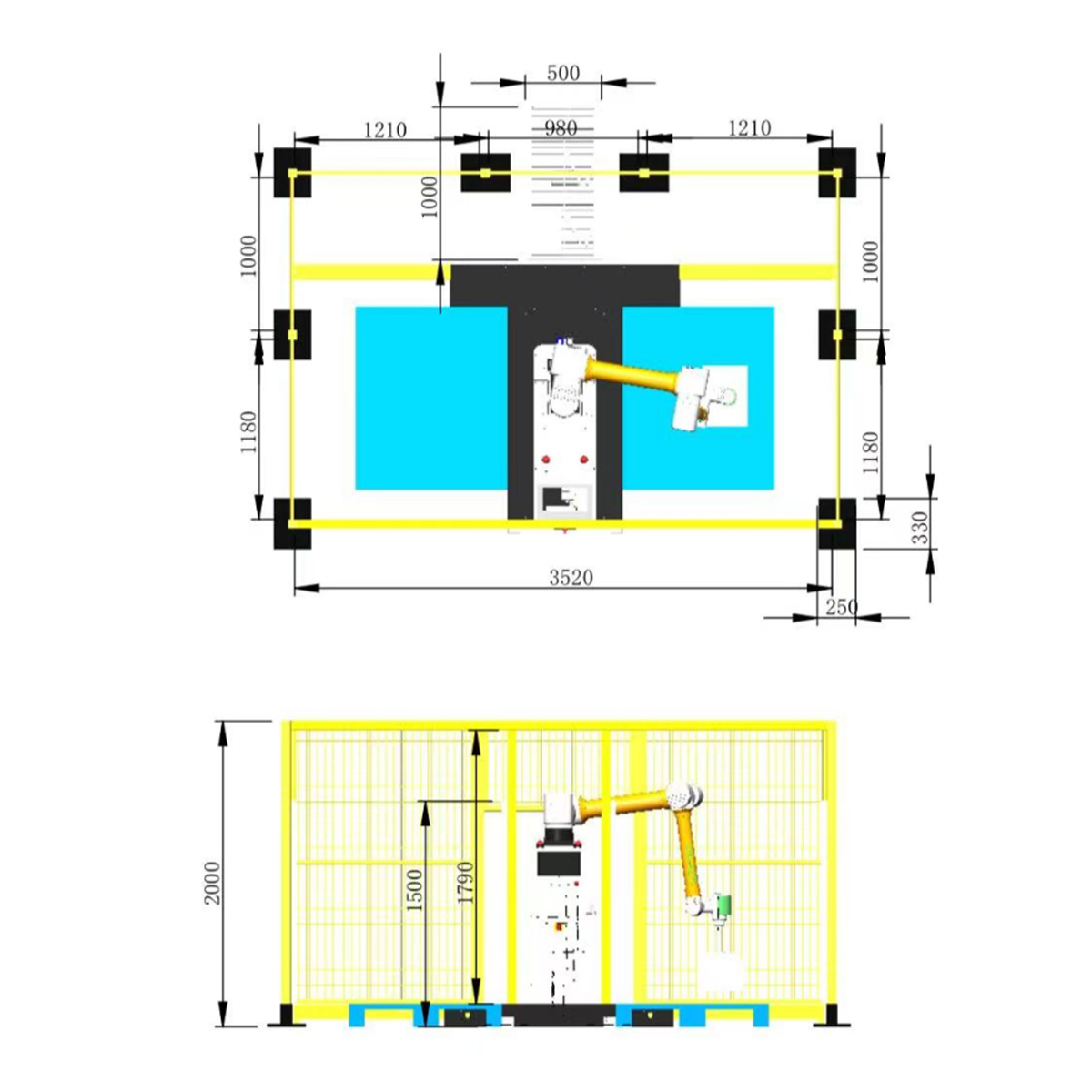

Safety functions | Optional: safety grating, safety fence, safety sensing carpet | |||

IP level | IP32 The robotic arm IP54, gripper, and other accessories all comply with IP32 | |||

Interface | Supports multiple security inputs and outputs, including emergency stop, security protection, manager mode, and manufacturer settings mode | |||

Safety functions | Emergency stop function, reserved external safety interface (can be controlled through I/O interface) | |||

Power | AC220V 10A+ | |||

Gas source | 6kgs | |||

* Maximum stack high refers to the use of a single box stack in a critical range (1200mm × 1200mm) in the case of using the maximum stack plate size (1200mm × 1200mm), can generally reach 1600mm. Size and placement of boxes. | ||||

码垛工作站组成 | ||||

Main components | Collaborative robots | |||

Operation and Control System | ||||

Electronic control components | Touch screen, controller, DC power kit and cable | |||

Special software for palletizing | ||||

Rack components | Convenient mobile fixed base | |||

Lifting column module and drag chain | ||||

End effector of rack components | Fixtures and suction cups | |||

Pneumatic group: air handling group, solenoid valve, air pipe at the end of the tool | ||||

5.Machine Configuration:

序号 | Machine part | Brand | Address |

1 | Hollow joint module | CN | |

2 | Lifting module | CN | |

3 | Reducer/gearbox | CN | |

4 | Programmable controller | CN | |

5 | Pneumatic components | AIRTAC | CN TAIWAN |

7、 Fence layout diagram

9、 The most advantages of a 20kg of palletizer:

1.Standard Palletizer With Height 1.65 Meters.

2.It takes 5 minutes to complete the admission of new products and 1 minute to complete the switching of product types.

3. Maximum Palletizing 8 Boxes/Min.

4. Light Weight And Removable.

5. 24 hours uninterrupted production.

6. Safe and stable,stop at one touch.

7. Can meet the requirement of producing two kinds of products at the same time to complete stacking.

8. Put into production within 2 hours after unloading the truck at the factory.

9. No required for experience in operating,just 1 hour learn to operate.

10. Disassembly time: Use a trailer to directly drag the palletizing base and positioning roller conveyor line to the designated location to complete.

Timon 8615638865245

Timon 8615638865245