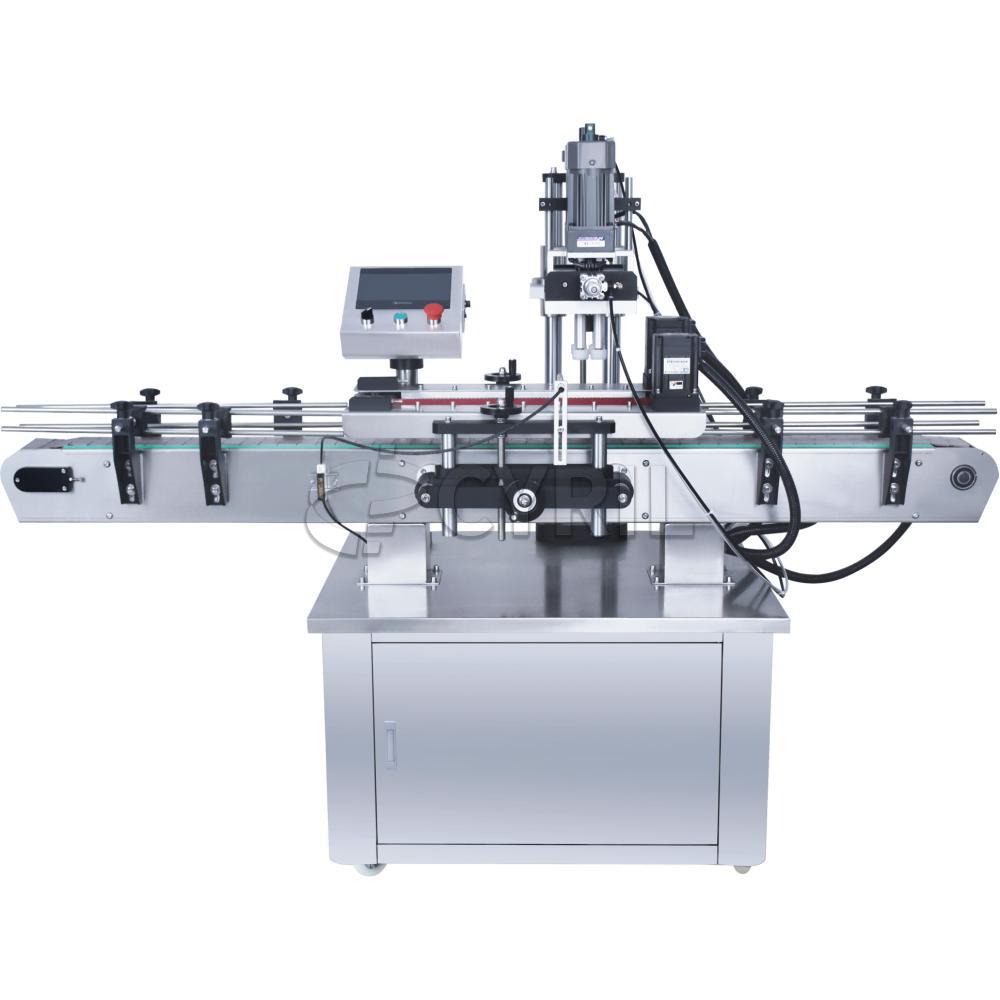

This automatic capping machine is suitable for round cap,spray/pump tightening, can work with existing filling line. Electrical control movement, strong stability; With positioning devices, standard Capping, easy to operate

This automatic capping machine is suitable for round cap,spray/pump tightening, can work with existing filling line.

Electrical control movement, strong stability;

With positioning devices, standard Capping, easy to operate;

Wide capping range suitable for different shapes and sizes;resolved the difficult problem on nozzle cap, pump cap, spray pumps, spray gun in hand button Capping;

Lock lid with adjustable speed can be adjusted according to different cap tightness.

Widely used in detergent shampoo, shower gel, hand cleaning gel, laundry detergent and many other daily chemical products.

1,PLC controlled , touch screen operation, integrated cap capping (automatic cap sorting/cap feeding can be option)

2, Automatic infeed cap and bottle position-setting and orientation, adjustable torque control.

3, Gentle manipulation, no scratch and injury to caps and containers

4, Easy changeovers, no need to change the fitting. just simple adjust.easy to operate.

one line capable of several bottle and caps.

5, Connected with filling machine and labeling machine easily

6, Module structure, manipulate on the touch screen, easy maintenance

Name | Automatic Twist Cap Capping Machine |

Model | PC-200 |

Application | Pump cap ,needle cap & standard cap capping |

Production | 1000-2000B/Hour |

Power | 220V 50Hz 0.7KW |

Cap height | 10-30mm |

Cap diameter | Φ 19--Φ 55mm(can be customized) |

Bottle height | 80-350mm |

Bottle diameter | Φ35-Φ100mm (can be customized) |

Air supply | 0.4-0.6Mpa |

Weight | 300Kg |

Dimension | 2000*1100*1550mm |

Hope our machine is what you need

Our clients come from over 80 countries.

The factory is located in Zhengzhou, Henan Province.

One year after-sales service guarantee.

High standard, high-quality machines.