call us(+86) 19137999990

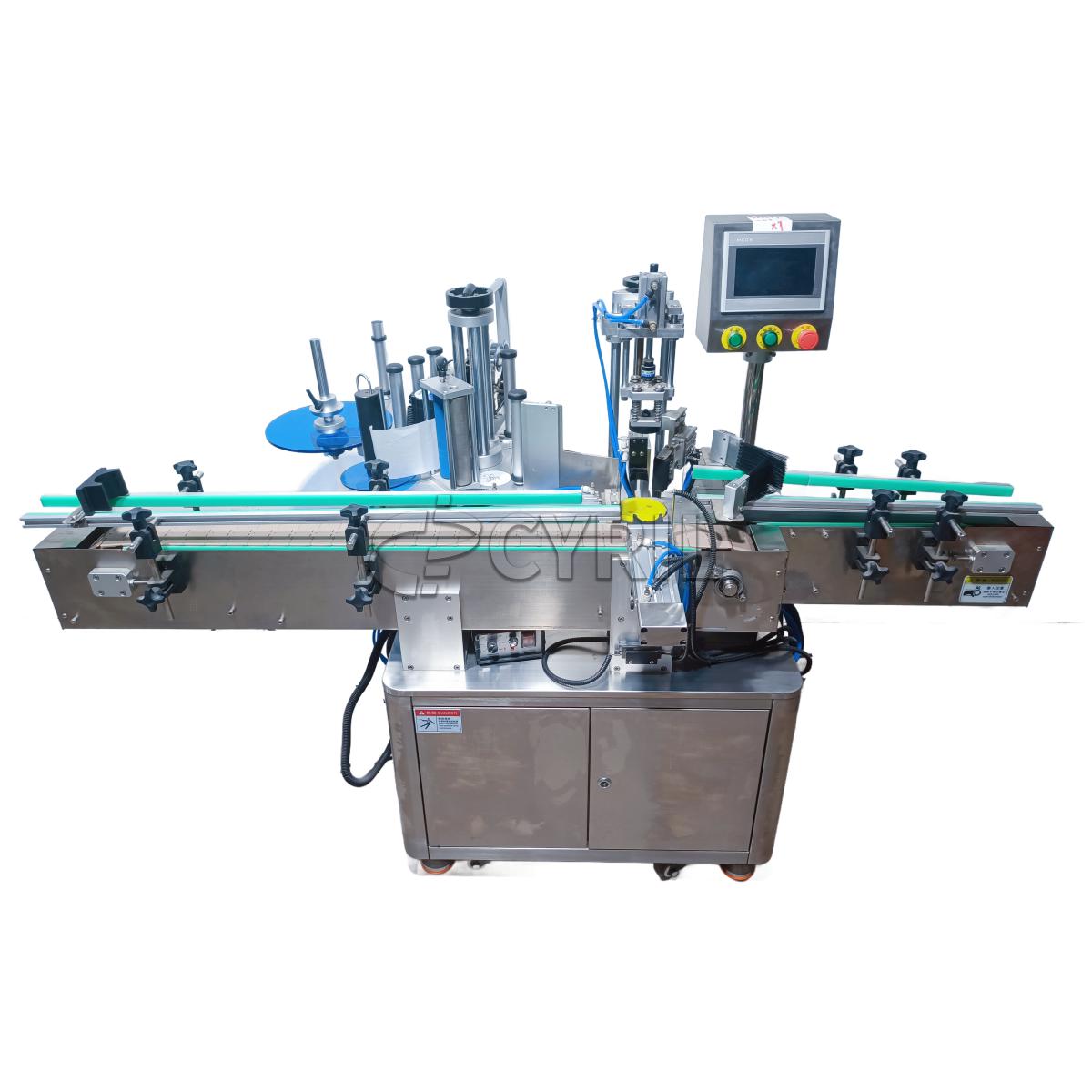

Suitable for single and double-sided labelling of flat bottles, round bottles, square bottles/ Multi-side labelling round bottles, multiple labelling to improve production efficiency, widely used in daily chemical, cosmetic, petrochemical, pharmaceutical and other industries.

Description :

Suitable for single and double-sided labelling of flat bottles, round bottles, square bottles, such as shampoo flat bottles, oil flat bottles. Multi-side labelling round bottles, multiple labelling to improve production efficiency, widely used in daily chemical, cosmetic, petrochemical, pharmaceutical and other industries.

Features:

(1)Wide range of application, can meet the round bottle whole circumference labelling or semi-circular labelling, simple switching between bottles and labels, easy to adjust;

(2)High labeling overlap, the labeling tape winding adopts the corrective mechanism, the labeling tape has no traces of winding, the labeling parts x/y/z direction tilt eight three degrees of freedom adjustable, adjusting no dead angle, labeling overlap is high;

(3)Good labelling quality, using standard tape coverage suppression, labelling flat, no wrinkles, improve packaging quality;

(4)Flexible and versatile, independent labelling bottles, with automatic bottle management function, can be single machine production, can also be connected to the production line;

(5)Intelligent control, photoelectricity automatic tracking, with no object not labelling, no label automatic correction and label automatic detection function, to prevent leakage and label waste;

(6)High stability, Delta PLC+WEINVIEW touch screen+Japan Keenshi label sensor+servo motor composed of advanced electronic control system, support equipment 7×24 hours operation;

(7)Easy adjustment, labelling speed, transfer speed, bottle dispensing speed can be stepless speed regulation, adjusted according to the need;

(8) Sturdy and durable, adopting three-point adjustment mechanism, making full use of the stability triangle, and the whole is sturdy and durable. Adopting stainless steel and high-grade alloy steel, in line with GMP production requirements.

Technical parameters:

Machine size | 2800x1650x1500mm |

Output speed | 25-60 sheets/min (Label size and length depends on specific situation) |

Bottle height | 30-350mm |

Bottle diameter | 20-120mm |

Label height | 15-175mm |

Label length | 25-300mm |

Labelling accuracy | ±1mm |

Voltage/power | 220 V 50/60 Hz 3.5 kW |

Weight | 450kg |

Hope our machine is what you need

Our clients come from over 80 countries.

The factory is located in Zhengzhou, Henan Province.

One year after-sales service guarantee.

High standard, high-quality machines.